The KEMSOLID process

Confining

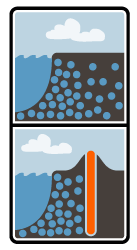

Sealing

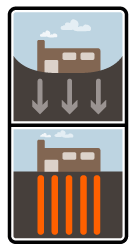

Separating

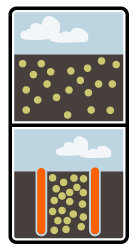

Stabilising

Infilling

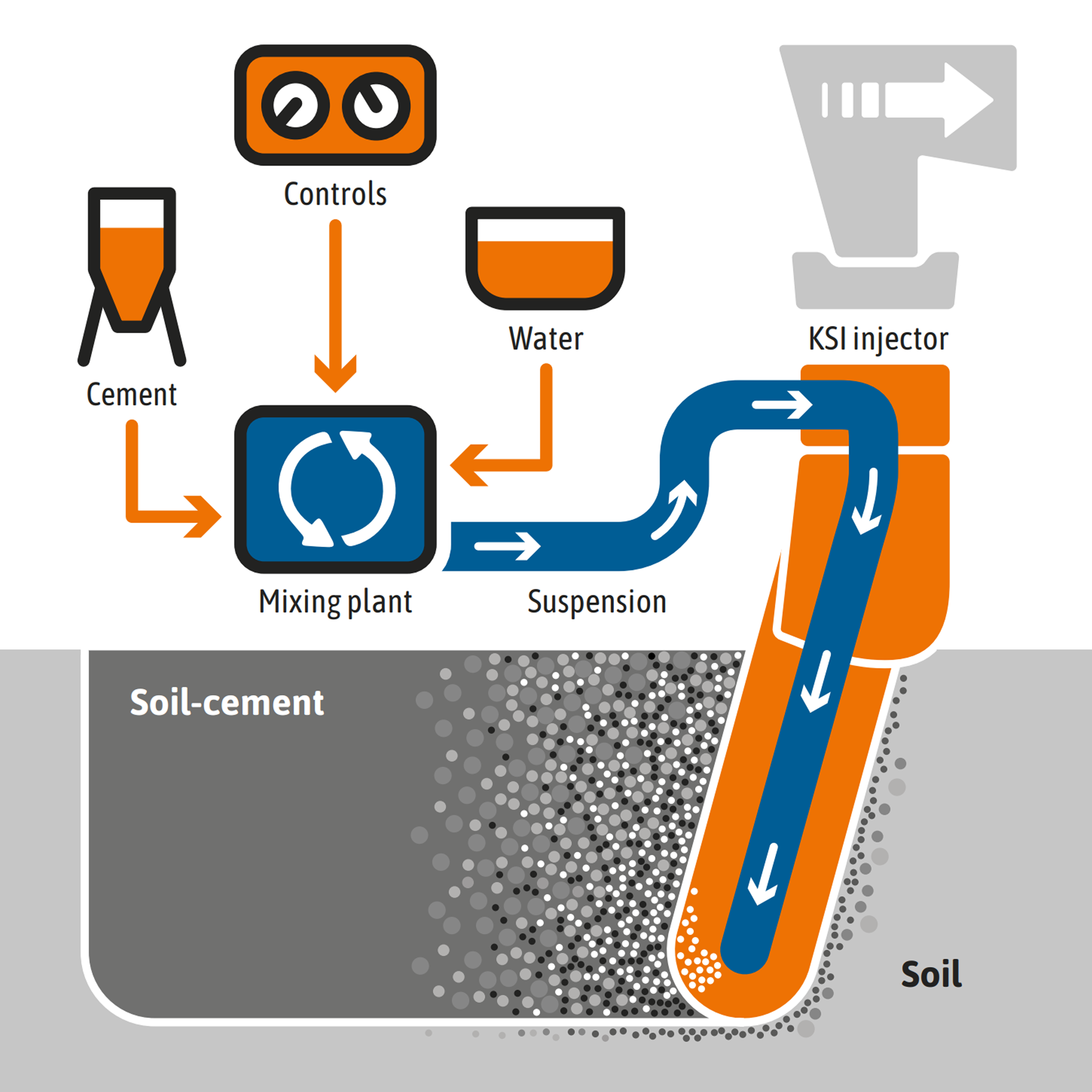

The KEMSOLID process is a technology used to produce soil-cement structures. (KSI) soil mixing attachments can be used on excavators, drilling and piling equipment for the production of soil-cement diaphragm and retaining walls.

Once the blade has penetrated to the required depth using the moving cutter chain, the binder solution is piped to the lowest point of the blade and injected into the soil. A mixing process follows until a uniform suspension with the required consistency of soil and cement has been produced. This creates an impermeable, stable soil-cement structure to the required dimensions.

Type and concentration of binder solutions will vary according to the load bearing and permeability levels required.

The KEMSOLID process is extremely versatile for addressing soil permeability and load bearing issues.

It can, for example, be used to seal excavations or enclose polluted areas. It can also be used to seal dams, dykes and other bodies of water as well as creating a barrier to prevent waves travelling from sources of vibration. In trenching and construction of large warehouses, it can be used to fill the gaps between supports.

It can also be used in applications where new roads are being built on soils with low load bearing capacity or the load bearing capacity must be increased to cope with extra weight or higher traffic speeds. These include some high-speed railway and motorway routes.

Process, animation & schematic representation

KEMSOLID is the name of KEMROC's new division dedicated to soil stabilization and ground improvement. This newly established business is focused on the development, testing and manufacture of KSI soil mixing attachments. Planning offices, construction companies, appraisers and clients also receive a full package of expertise from foundation engineering specialists.

Process

The process involves using a standard excavator with a soil mixing attachment whose blade with moving cutter chain penetrates into the ground and injects a binder material which is pumped from a semi-mobile mixing plant via hoses to the excavator. After curing, a homogenous, stable, dense soil-cement structure has been created. Depending on the length of the blade, KSI soil mixing attachments can be mounted on standard excavators with operating weights from 40 to 120 tons.

The KSI 7000 model can be equipped with blades suitable for mixing depths of 5, 6 or 7 meters, while the larger KSI 12000 model can take blades for mixing depths of 6, 8, 10 or 12 meters.

Depending on the application, the blades can be produced with cutter plates for different mixing widths. The technology evolved from rock cutting attachments, so operating in difficult, stony conditions is not a problem.

At the same time, it is also possible to integrate the soil-cement structure into solid ground or rock. The main reasons for using the KEMSOLID process are as follows:

•Rapid soil improvement within a very short time

•Increasing load bearing capacity and reducing permeability

•Avoidance of deep excavations and large movement of material

•Minimizing extracted materials to be recycled

•Saving transport, reducing energy and CO2 pollution

•Saving of resources and expensive building materials

The KEMSOLID process as animation.

In contrast to the use of conventional diaphragm wall producing machinery, the installation of diaphragm walls using the KEMSOLID process is not carried out segment by segment, but continuously over the entire length of the structure.

Misalignment of any individual segment is therefore eliminated. The blade of the KSI attachment mixes the soil in-situ continuously over the entire installation depth.

This ensures that the soil-cement structure is uniformly homogeneous in all aspects after curing.

As the chain is fitted with dragon teeth cutters, the soil-cement structure can be easily integrated into existing rock deposits to ensure proper sealing at the boundaries.

KEMSOLID Process schematic

A completed soil-cement structure exposed for inspection and testing.

You have any questions? We are here for you.