Rock cutting technology for soil stabilization – fast, efficient and environmentally friendly.

KEMSOLID - build on solid foundations

Explore Kemsolid Company Profile

Get to know Kemsolid’s story, solutions and achievements. View our company profile to discover how we can help you succeed.

KEMSOLID

KEMSOLID is the name of KEMROC’s division dedicated to soil stabilization and ground improvement. This newly established business is focused on the development, testing and manufacturing of soil mixing attachments. Planning and design firms, construction companies and clients also receive a full package of expertise and advise from foundation engineering specialist.

KEMSOLID offer technologies for creating a homogenous, impermeable and frost resistant soil-cement structures . Depending on soil conditions and desired load bearing requirements, various concentrations of cement and binder fluid are used.

There are a wide range of applications where KEMSOLID technologies can be used to improve the load bearing and permeability characteristics of soils. It can be used to seal large excavations or polluted areas. It can also be used to seal dams, dikes and bodies of water as well as creating a barrier to ground-borne vibration. It can be used to shore trenches and strengthen the ground supporting large buildings such as logistic warehouses. It can also be used where traffic routes have to be built on poor ground or where the foundations of existing roads have to be improved to allow for higher traffic loads and speeds. These include, for example, construction sites for rapid transport and motorways.

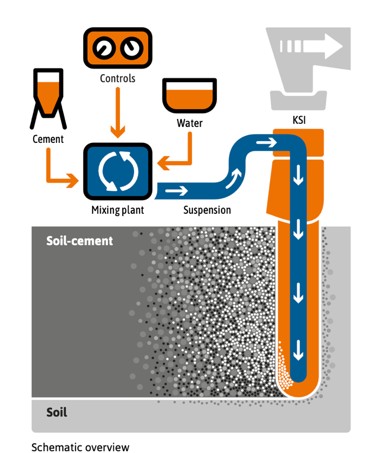

KEMSOLID TSM Technology

The TSM (Trench-Soil-Mixing) technology is a method of creating in-situ soil cement structures. KSI soil mixing attachments can be installed on excavators or drilling and pilling equipment to achieve production of soil–cement diaphragm and retaining walls. Once the trencher has achieved the required depth using the moving cutter chain binder solution is piped through to the lowest point of the trencher and injected into the soil. A mixing process follows until a uniform suspension with the required consistency of soil and cement has been reached. This creates an impermeable, stable soil-cement structure to the required dimensions. Type and concentration of binder solutions will vary according to load bearing and permeability levels required.

Since this method comes from rock grinding technology, handling small unforeseen obstacles is easily overcome. At the same time, it is also feasible to integrate the soil- cement structure into solid ground or rock.

A completed soil-cement structure exposed for inspection and testing.

You have any questions? We are here for you.