The Kemsolid TSM solution

The TSM or Trench-Soil-Mixing is a method of creating in-situ soil cement structures. KSI soil mixing attachments can be installed on excavators or drilling and piling equipment to achieve production of soil-cement cut-off and retaining walls. Once the blade has achieved the required depth using the moving cutter chain a binder is piped through to the lowest point of the blade and injected into the soil. A mixing process follows until a uniform suspension with the required consistency of soil and cement has been reached. This creates an impermeable, stable soil-cement structure to the required dimensions. Type and concentration of a binder will vary according to compressive strength and permeability levels required. Since this method comes from rock grinding technology, handling small unforeseen obstacles is easily overcome. At the same time, it is also feasible to integrate the soil-cement structure into solid ground or rock.

The blade of the KSI attachment continuously mixes the soil in-situ over the entire installation depth. This ensures that the soil-cement structure is uniformly and thoroughly mixed throughout the installation depth.

The Kemsolid TSM solution is extremely versatile for addressing soil permeability and load bearing issues. It can, for example, be used to seal excavations or contain contaminated areas. It can also be used to seal dams, dykes and other bodies of water as well as creating a barrier to dampen waves travelling from sources of vibration. In trenching and construction of large warehouses, it can be used to improve the soil between supports. It can also be used in applications where new roads are being built on soils with low load bearing capacity or the load bearing capacity must be increased to cope with extra weight or higher traffic speeds. These include some high-speed railway and motorway routes.

Process sequence

Step 1: Excavation of a guide trench (depth approx. 50cm, width same as required)

Step 2: Positioning of the mixing blade mounted on the excavator or pilling rig

Step 3: The mixing blade is driven into the ground up to designed depth by using grout or water pumped through

Step 4: After reaching the required depth carrier moves slowly backwards and at the same time the existing soil is cut and mixed with the grout. Typical chain speed of the trencher is 2 – 2.5 m/s and typical carrier speed is 10-15 m/hr.

Step 5: Reinforcing elements required for structural purposes can be inserted into the completed wall.

Depending on soil type and local ground conditions, production rates of more than 100 linear meters per day are possible.

The KSI range of mixing attachments

KSI soil mixing attachments are available in three sizes and can be supplied with a range of blade lengths. The KSI 7000 model can be equipped with blades suitable for mixing depths of 4,

5, 6 or 7 meters, while the larger models KSI 12000 and KSI 16000 can take blades for mixing depths from 6 to 12 and from 6 to 16 meters respectively. Depending on the application, the blades can be produced with cutter plates for different mixing widths. Thanks to the ability to switch between dragon tooth and round attack picks, the structure can be integrated into layers of weathered rock while maintaining a sealed interface.

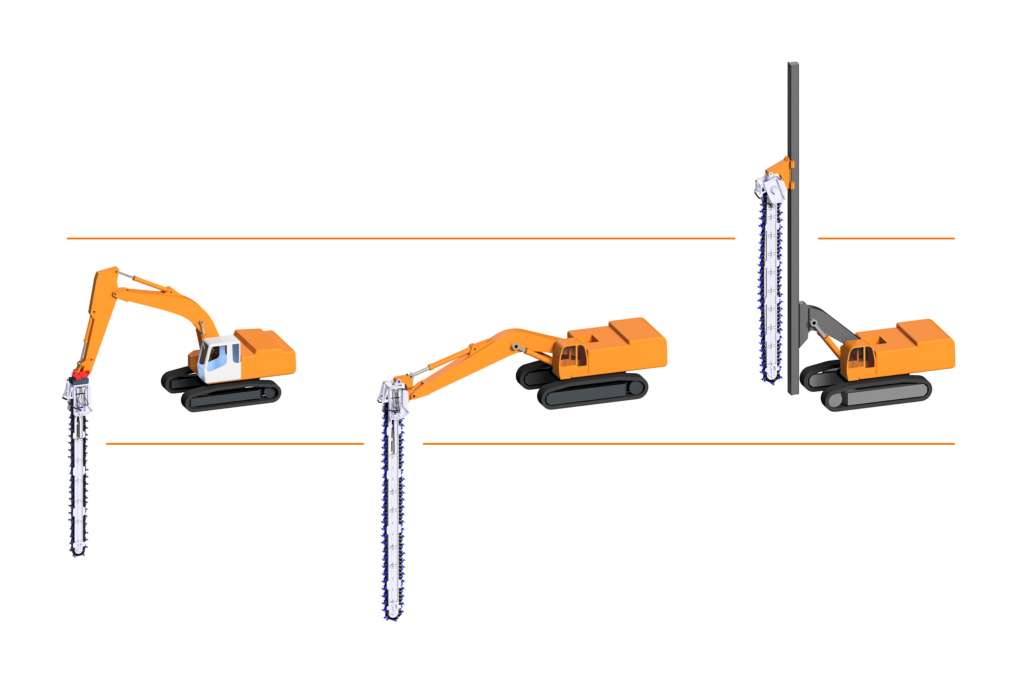

KSI 7000

Excavater with standard stick

KSI 12000

Excavator without stick

KSI 12000

Piling excavator

Slurry /binder characteristics

The slurry mix design and components depend on many different factors, especially soil conditions and purpose of the application.

Typical components are:

- Cement

- Bentonite

- Additives

- Water

- Others (e.g. fly ash)

Other common characteristics are:

- w/c ratio 0,5 – 2,0

- amount of cement 200 – 700 kg /m3 slurry

Options for Kemsolid (not required)

Quality control

Quality control of soil mixing is very important. If possible, before starting a project, preliminary tests are recommended.

Hardware and software mounted on the mixing attachment and on the excavator collect production parameters. Performance, quality and quantity data is recorded in real time.

The most important parameters are:

- Mixing depth

- Mixing width

- Chain speed

- Carrier speed

- Slurry volume

- Hydraulic oil flow and pressure

Attachment and adaptor options

- Option 1: Excavator adaptor plate with standard hole patterns for use with quick couplers (e.g. Lehnhoff, OilQuick, etc).

- Option 2: A mechanical hook for attachment to excavators directly to the boom.

- Option 3: Adapter plate for drilling and piling rigs.

Kemsolid Partner Offers Digital Recording of Production

Kemsolid partner companies offer hardware and software mounted on the mixing attachment and on the excavator to capture digital recording of production parameters. Performance, quality and quantity data is recorded in real time.

Maintenance free and reliable measurement of the mixing depth

Robust, vibration resistant sensors continuously record po- sition of boom segments and the attachment. The data is processed as a kinematic model providing accurate infor- mation regarding mixing depth, speed of advance as well as discharge combined with oil pressure and volume.

Sensor

Sensor

Sensor

Sensor

High-precision positioning of the mixing attachment

Satellite-based navigation via two RTK GNSS/GPS antennas processed data acquisition are integrated in a compact system mounted on the excavator, providing optimal oper- ator assistance for the TSM process. All essential informa- tion is available on a single monitor in the operator’s cab.

GNSS/GPS Antennen

GNSS/GPS Antennen

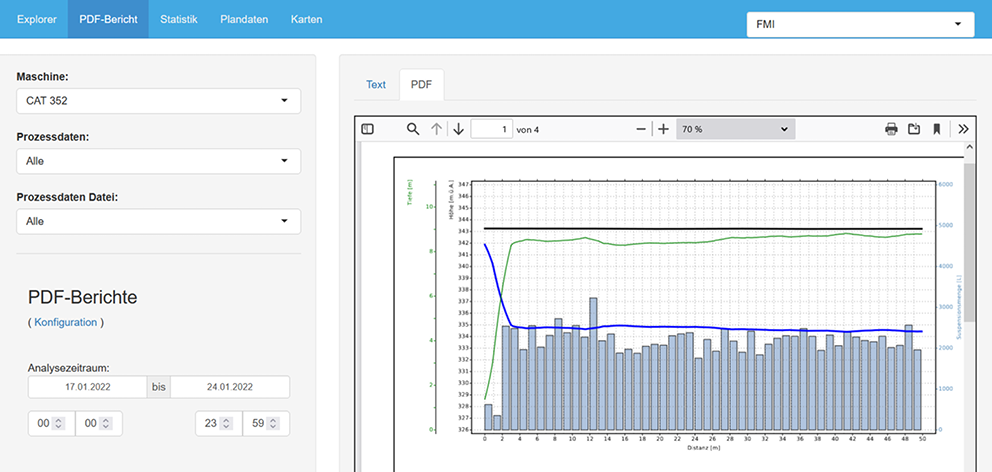

Data management with immediate transparency

PDF reporting and interactive data analysis in a web based application tailored to foundation engineering. We rec- ommend collecting the following data during the TSM process: surface elevation, bottom of the slot, amount of suspension used and location (GPS).

Diagramm

Pictures & Videos from KSI 12000

The KSI 12000 is being used in the TSM technology to create a waterproof reinforced concrete wall, which will be integrated into the weir structure to construct a rainwater retention basin.

Watch Our Attachments In Action!

Pictures & Videos

Pictures and videos from KSI 7000

Contact Us Now!

Special foundation work products

Other products for use in special foundation work

You have any questions? We are here for you.