Smarter Soil Mixing Solution for Flood Protection: Kemsolid KSI 12000 Building Stronger Foundations in Germany

Job Site Report

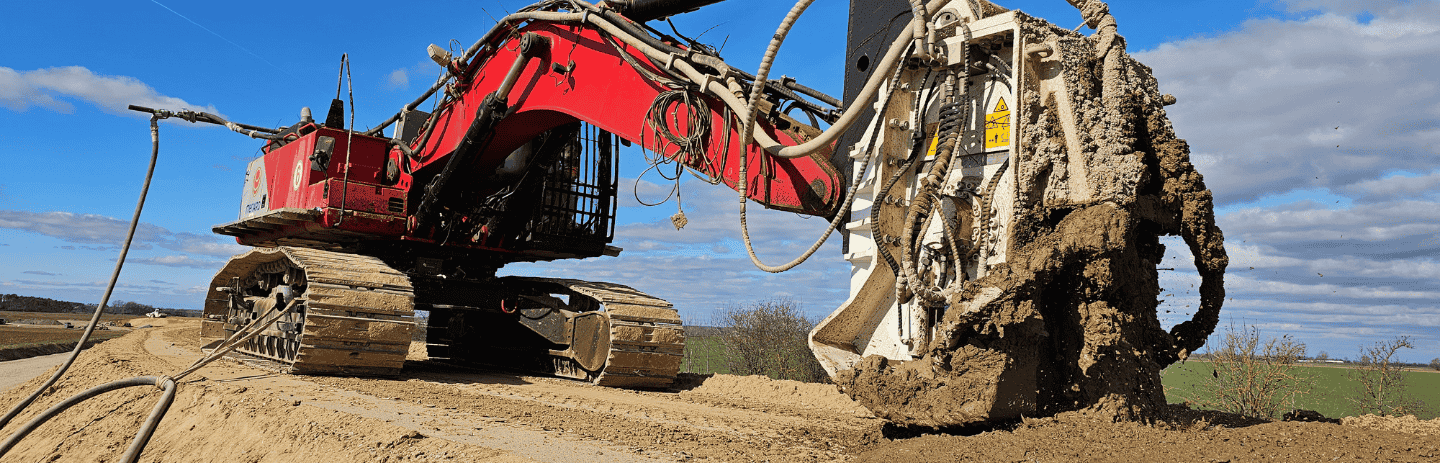

KEMSOLID KSI 12000 Soil Mixer in Flood Protection Project – Strehla, Germany

Introduction: Smart Ground Improvement with KEMSOLID

A pioneer in foundation industry, Menard GmbH deployed the KEMSOLID KSI 12000 soil mixer, powered by KEMROC technology, for a critical ground improvement project in the surrounding of Strehla, Saxony, Germany. The focus was on soil improvement and subsoil stabilisation of a flood protection dam along the Elbe River. This project demonstrates how the Kemsolid process and innovative soil mixing technology redefine deep soil mixing and in-situ soil stabilisation for specialised civil engineering applications.

Project Scope: In-Situ Soil Stabilisation for Flood Defense

The job site involved restoring and strengthening a 1,200 m long segment of a flood protection dam, measuring 4 m high and 6 m wide. During the project, the dam was increased in height, requiring a solution that would seamlessly integrate the new structure with the existing one. The ground conditions inside the flood dam consisted of heterogeneous soils with varying levels of compaction and permeability, making soil stabilization critical to ensure durability and waterproofing. The application required the installation of a sealing wall (diaphragm wall) from the crest of the dam, reaching 7.5 m deep. This diaphragm wall served as a vital connection between the “old” and “new” sections of the flood protection dam, ensuring structural integrity and preventing seepage. The KSI 12000’s mixing sword enabled the construction of a seamless wall, blending in-situ soils with stabilizing binders to enhance both durability and water resistance.

One of the biggest challenges was the presence of water pipelines crossing the dam. The soil mixing process was adjusted on-site by modifying the penetration depth of the mixing sword to avoid damaging critical infrastructure, showcasing the precision and adaptability of this soil stabilizer machine.

Performance of the KSI Soil Mixer

Mounted on a 50-ton Caterpillar 345 excavator, specially adapted for this application, the KSI deep soil mixing attachment achieved up to 105 linear meters of diaphragm wall per day. This performance far exceeded traditional soil-cement mixing process methods. Traditionally, Menard uses a drill rig with an attached multimixer to perform mixed-in-place soil stabilization. However, to bring a drill rig onto the dam, the crest had to be widened, requiring significant excavation and removal of material afterward. By contrast, the KSI attachment allowed the work to be carried out with a much smaller carrier machine, eliminating the need for costly preparatory earthworks.

As a result, the KSI system not only outperformed conventional methods, which typically managed only 60–80 meters daily, but also proved more practical and less disruptive on constrained job sites. With further optimization of water supply and mixing plant logistics, performance expectations are projected to reach up to 140 meters per day, establishing the KSI soil mixer as a new benchmark for productivity in ground improvement techniques.

The in-situ mixing cutter also demonstrated exceptional efficiency in wear resistance, consuming just 30 cutter teeth across the first 700 m of the project. By ensuring seamless mixing, the KSI 12000 guaranteed continuous, uniform walls with no gaps, a critical factor in flood defense construction.

Benefits of the Kemsolid Process

The KSI soil mixer is more than just construction site equipment; it represents a leap forward in soil mixing technology. By using the Kemsolid process:

- Mass soil mixing and trench soil mixing technology become faster, safer, and more reliable.

- On-site soils are improved without excavation, transportation, or replacement, reducing environmental impact.

- The fine, homogenous mixture produced ensures the long-term strength of retaining wall soil mixing and foundation structures.

- The use of an excavator mounted soil mixer brings mobility and adaptability, eliminating the need for large, complex rigs.

Customer Experience and Evaluation

For Menard GmbH, this was the first deployment of the KSI 12000 mass mixing excavator attachment after earlier trial runs. Despite initial adjustments, operators quickly adapted, supported by Kesmolid experts. The customer reported that the KSI significantly outperformed conventional soil mixing methods, proving to be the most efficient solution for mass soil stabilization and foundation soil stabilization.

Conclusion

The Kemsolid KSI 12000 soil mixer has proven itself as an innovative and reliable solution for ground improvement, soil remediation, and flood protection projects. Its ability to deliver deep soil mixing with high productivity, precision, and eco-friendly operation demonstrates why Kemsolid Powered by KEMROC is a leader in soil mixing attachments for excavators. By setting new benchmarks in soil improvement and specialised civil engineering, the KSI series continues to define the future of soil mixing processes, ensuring sustainable infrastructure and resilient foundations.

Discover the KSI Difference!

Ready to elevate your next project? Contact Kemsolid today to learn how the KSI range can help you build on solid foundations.