Kemsolid Technologies – Advanced Soil Stabilization & Ground Improvement

Kemsolid, the specialized brand by KEMROC, is dedicated to ground improvement and soil stabilization, offering cutting-edge solutions for civil engineering projects. Kemsolid technologies provides a highly efficient method for soil-cement structure creation, addressing challenges in load-bearing capacity, permeability, and environmental sustainability.

The Kemsolid TSM Technology can be applied in the following eight applications:

- Confining – Containing and securing soil structures.

- Sealing – Preventing water infiltration and leakage.

- Separating – Creating barriers to divide soil layers.

- Stabilizing – Strengthening soil for construction purposes.

- Shoring – Providing structural support for excavation areas.

- Stabilizing for high-speed – Reinforcing ground conditions for high-speed rail and road projects.

- Dam stabilisation – Strengthening and waterproofing dams.

- Creating retaining walls – Constructing soil-cement retaining walls for slope stability.

These applications highlight the versatility and effectiveness of Kemsolid TSM Technology in advanced ground improvement and soil stabilisation projects.

Innovative Soil Mixing Solutions

Kemsolid utilizes KSI soil mixing attachments designed for excavators, drilling rigs, and piling equipment to create diaphragm and retaining walls in-situ. By integrating Trench-Soil-Mixing (TSM) and Mass-Soil-Mixing (MSM) technologies, Kemsolid ensures optimal soil performance.

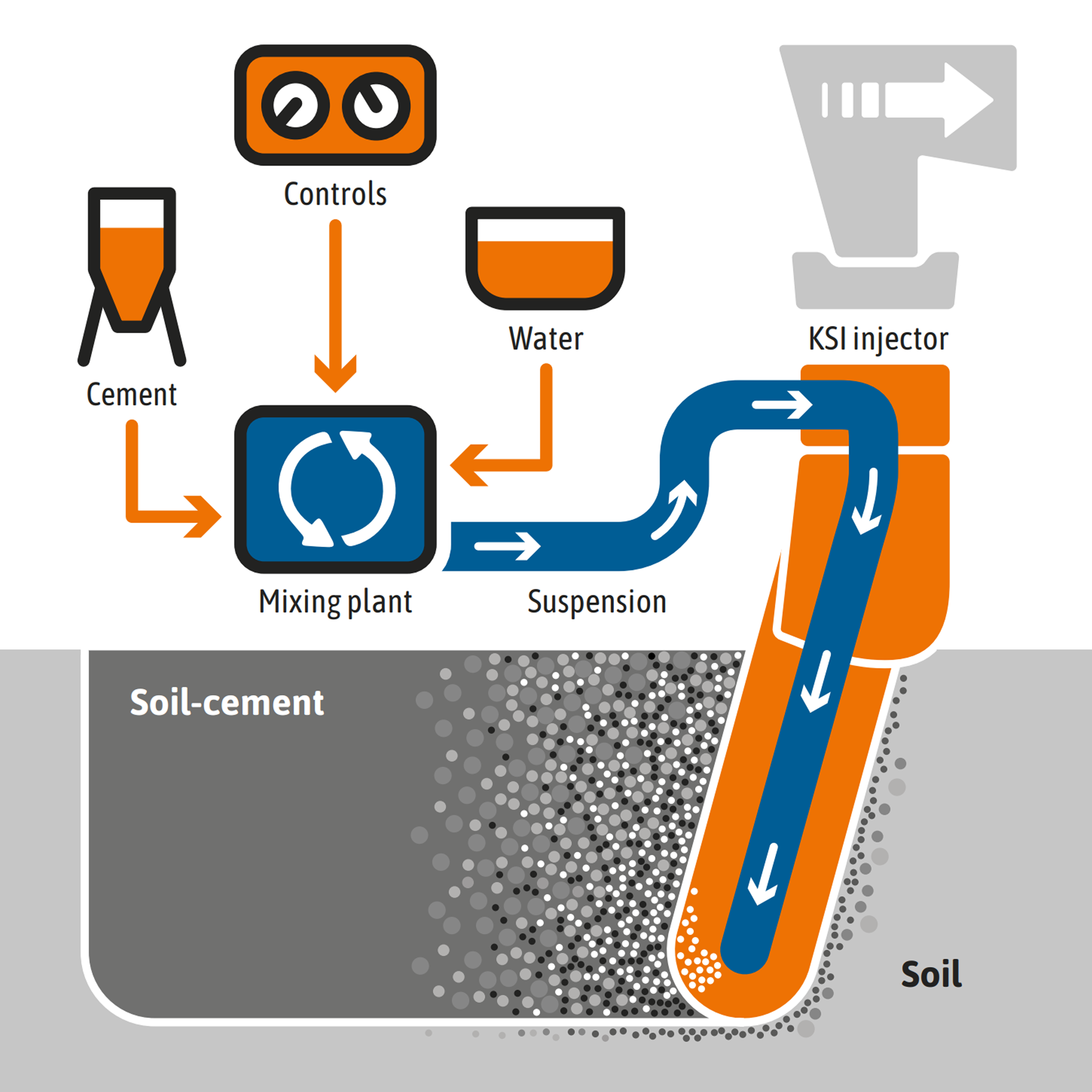

How It Works:

- A moving cutter chain penetrates the soil to the required depth.

- A binder solution is pumped through to the lowest point and injected into the soil.

- A continuous mixing process follows, ensuring a homogeneous and impermeable soil-cement structure.

Binder solutions are tailored based on load-bearing and permeability requirements, making the KEMSOLID process highly adaptable.

Why Choose Kemsolid?

- Faster Soil Stabilization – Rapid improvement in soil properties with minimal excavation.

- Enhanced Load Bearing – Strengthens weak subsoil for construction.

- Minimal Material Removal – Reducing excavation, transport, and disposal costs.

- Eco-Friendly & Sustainable – Low CO₂ emissions, energy-efficient, and reduced material wastage.

- Seamless Integration – Works effectively with both soft soil and rock layers.

Kemsolid Technologies schematic

A completed soil-cement structure exposed for inspection and testing.

Kemsolid Mixing Attachments

The KSI Range of Mixing Attachments

KSI soil mixing attachments are available in three sizes for mounting on excavators between 35 and 200 ton operating weight and can be supplied with a range of blade lengths. The KSI 7000 model can be equipped with blades suitable for mixing depths of 4, 5, 6 or 7 meters, while the larger models KSI 12000 and KSI 16000 can take blades for mixing depths from 6 to 12 and from 6 to 16 meters respectively. Depending on the application, the blades can be produced with cutter plates for different mixing widths.

The KSI series in 3 sizes to match different project requirements:

- KSI 7000: Mixing depths of 4m – 7m, compatible with 35-55 t excavators.

- KSI 12000: Mixing depths of 6m – 12m, for 50-120 texcavators.

- KSI 16000: Mixing depths of 6m – 16m, for 75-200 t excavators.

These attachments offer customizable cutter widths, high-torque drive motors, and hydraulic chain tensioning for superior performance.

The KDM Range of Mixing Attachments

Mixing attachment in the KDM range are available in three sizes for 25 to 50 ton excavators. A variety of mixing depths can be achieved by changing the extension segments.

The KDM series in 3 sizes to match different project requirements:

- KDM 120: Mixing depths of 6m, compatible with 25–40 t excavators.

- KDM 150: Mixing depths of 6m, for 30–40 t excavators.

- KDM 165: Mixing depths of 6m, for 35–50 t excavators.

Revolutionizing Foundation Engineering

Kemsolid technologies eliminates the need for conventional segment-by-segment diaphragm wall construction. Instead, it creates continuous soil-cement structures, ensuring uniform strength and stability.

Contact Us Now!